Average

lead time

lead time

1

Week

Lifecycle

increase

increase

0

X

On-time

delivery

delivery

0

%

Avg. savings switching from

stainless steel to coated carbon

stainless steel to coated carbon

0

%

ECOAT.US has a long history of adding value with Ecoat, liquid, and powder coating services. Our patented application technology allows us to serve major OEMs in North America with precision and professionalism.

Our coating systems are designed to extend your products’ life and protect them from corrosive environments. We are committed to environmentally responsible process materials and applications.

National footprint to serve your coating needs Five patents. Two trademarks.

(With more to come)

Today’s greatest industries require durable coating solutions for environmental, chemical, and technical challenges.

Since 1995, ecoat.us has partnered with clients spanning the private and public sectors to keep individual parts and entire infrastructures performing at maximum efficiency for longer in the most demanding environments.

Our proprietary coating processes and industry-specific expertise have already helped 400+ clients extend the lifetime of their parts, cut operating costs, and prevent devastating failures in the field. How might we do the same for you?

Discover a versatile range of coatings that provide enduring protection against corrosion, abrasion, and other environmental challenges tailored to your unique applications.

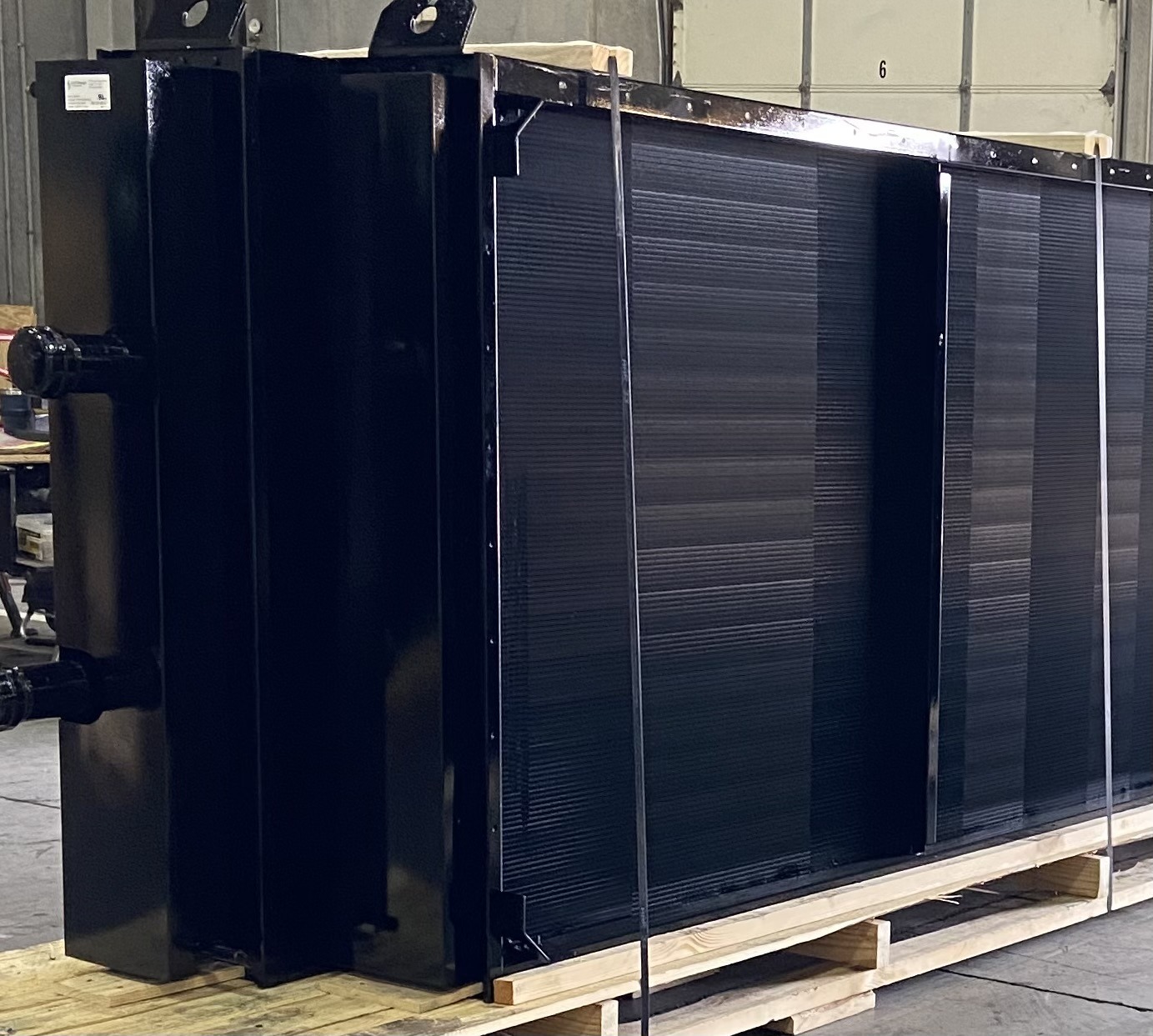

Find the specs you’re looking for in our catalog. Then partner with a team that has the experience and capacity to handle confidential materials, long development cycles, and over-sized parts.

Custom request? We’ve got the know-how, team, and track record to create custom solutions that’ll keep your parts performing in any environment.

Two Of Our Biggest Challenges Are Corrosion Issues And The Need For Added Protection For Parts In A Timely Manner

Ecoat.us provided their ZPEX process to our standard parts without additional machining or preparation, helping us avoid stainless steel cost-effectively.

Ecoat.us has added true value to our product line. We service the energy industry in the upstream production market. Two of our biggest challenges are corrosion issues and the need for added protection for parts in a timely manner.

Ecoat.us used the ZPEX process for our standard parts without additional machining or preparation, helping us avoid stainless steel cost-effectively. Ecoat.us also delivered our completed project within one-third of the time it took other coating companies.

We can meet our customers’ needs thanks to Ecoat.us and continue to look for further applications of ZPEX in our product lines.

We’ve coated satellites in space, munitions sent abroad, and valves submerged deep in the ocean. You’ll find us specified in technical requirements for many products across industries.

Smaller coating companies just don’t have the capacity or process to prioritize your parts. With four locations across the US and over 25 years of experience, we guarantee consistent results delivered in record time, every time

As a private company, we don’t get tangled up in bureaucracy or red tape. We can scale our team overnight to accommodate any size request.

We’ve integrated technology into every aspect of our coating processes to guarantee reliable results and clear communication. Log into your client portal to track the status of your parts, download certifications, and chat with us whenever you need.